Materials Characterization Group (“process-structure-property”)

GROUP LEADER: Iwona Jóźwik, PhD

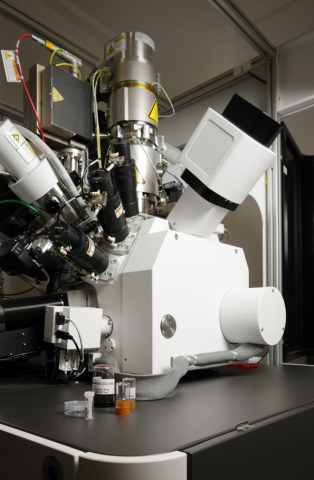

Dr. Iwona Jóźwik obtained her Master's degree in Physics from the Faculty of Mathematics and Physics at the University of Maria Curie-Skłodowska in Lublin, Poland, in 2001. Continuing her academic pursuits, she earned her PhD in Physics in 2006 from the Faculty of Applied Physics and Mathematics at the Gdańsk University of Technology, Poland. She specializes in scanning electron microscopy (SEM) and its complementary techniques, including EDS (Energy Dispersive X-ray Spectroscopy), EBSD (Electron Backscatter Diffraction), and sample preparation utilizing focused ion beam (FIB) techniques.

Her research focuses on the structural characterization of materials using microscopy techniques, with a particular emphasis on employing low-energy scanning electron microscopy to directly visualize damage in ion-irradiated materials. Her contributions aid in understanding material behavior under extreme conditions, providing insights for various industrial and scientific applications.

Scopus Author ID: 16039084500

Web of Science ResearcherID: GBF-6750-2022

ORCID: 0000-0001-5750-2691

STRUCTURE OF THE GROUP

- Iwona Jóźwik (Research Group Leader)

- Ryszard Diduszko (Technical and Research Specialist)

- Magdalena Wilczopolska (Technical and Research Specialist)

- Magdalena Gawęda (PostDoc)

- Anna Kosińska (Research Specialist)

- Damian Kalita (PostDoc)

- Przemysław Kot (PostDoc)

- Michał Stróżyk (PostDoc)

- Witold Chromiński (Research Specialist)

DESCRIPTION OF THE SCIENTIFIC ACTIVITIES

The research progress within the Materials Characterization Group has been a dynamic and multifaceted endeavor, with a keen focus on advancing our understanding of materials' behavior in extreme environments commonly encountered in nuclear, energy, and chemical industries. Our efforts have been dedicated to the comprehensive characterization and development of novel materials, including steels, alloys, and coatings, tailored to withstand the harsh conditions imposed by high temperatures, corrosive atmospheres, friction, and various other factors intrinsic to these applications.

Our research activities have been coordinated to attain a profound comprehension of the intricate processes unfolding within the microstructures of materials under such challenging conditions. These investigations rely upon a suite of cutting-edge experimental techniques, encompassing Transmission Electron Microscopy (TEM), Scanning Electron Microscopy (SEM), Focused Ion Beam (FIB) technique, Electron Backscatter Diffraction (EBSD), and Energy-Dispersive X-ray Spectroscopy (EDS). Additionally, we employ X-ray Diffraction (XRD) and in-situ Raman spectroscopy, especially at elevated temperatures, to scrutinize structural alterations, interface phenomena, and chemical transformations that unfold during the utilization of materials.

Our research framework firmly adheres to a closed-loop approach, where a symbiotic relationship between multiscale computer modeling efforts and experimental data is the cornerstone. This exchange of information facilitates a holistic understanding of materials, spanning from theoretical modeling and structural characterization to functional property assessments, thereby enriching our insights into material performance.

The core research pillars of our group encompass the following key areas:

Development of irradiation-resistant body-centered cubic (BCC) concentrated solid solution alloys (CSAs) for nuclear fusion applications: We are dedicated to pioneering new materials that exhibit exceptional resilience to irradiation, particularly in the context of nuclear fusion. These materials hold immense promise for the advancement of fusion energy technologies.

Development of amorphous silicon oxycarbide-based protective coatings for cladding materials in nuclear reactors: Our research endeavors extend to the development of advanced protective coatings, particularly in the form of amorphous silicon oxycarbides, which are tailored to enhance the longevity and reliability of cladding materials within nuclear reactors.

In-situ Raman spectroscopy study of phase transformations in materials across a broad temperature range: Employing in-situ Raman spectroscopy, we delve deep into the real-time examination of phase transformations within materials spanning a wide temperature spectrum. This investigation provides valuable insights into the dynamic behavior of materials under varying thermal conditions.

Development of high-entropy alloys (HEA) and advanced ferritic alloys (AFA) for application in fission lead-cooled and molten salt fast reactors: Our efforts extend to the design and development of high-entropy alloys and advanced ferritic alloys, which hold great potential for deployment in fission reactors, particularly lead-cooled and molten salt fast reactors.

The research conducted by the Materials Characterization Group has made significant strides in advancing our understanding of materials' behavior under extreme conditions. Our commitment to innovation and collaboration between experimental and theoretical aspects of materials science ensures that our findings contribute meaningfully to the progress of nuclear, energy, and chemical industries.

PUBLICATIONS

M. Gawęda, P. Jeleń, M. Bik, M. Szumera, Z. Olejniczak, M. Sitarz; Spectroscopic studies on phosphate-modified silicon oxycarbide-based amorphous materials; Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy; Vol. 291 (2023) p. 122341; DOI: 10.1016/j.saa.2023.12234

D. Kalita, I. Jóźwik, Kurpaska, Y. Zhang, K. Mulewska, W. Chrominski, J. O’Connell, Y. Ge, W.L. Boldman, P.D. Rack, Y. Wang, W.J. Weber, J. Jagielski, The microstructure and He+ ion irradiation behavior of novel low-activation W-Ta-Cr-V refractory high entropy alloy for nuclear applications, Nucl. Mater. Energy. 37 (2023). https://doi.org/10.1016/j.nme.2023.101513.

D. Kalita, K. Mulewska, I. Jóźwik, A. Zaborowska, M. Gawęda, W. Chromiński, K. Bochenek, Ł. Rogal, Metastable β-phase Ti-Nb alloys fabricated by powder metallurgy: effect of Nb on superelasticity and deformation behavior, Metallurgical and Materials Transactions A, (2024), DOI: 10.1007/s11661-023-07285-5

M. Gawęda, M. Wilczopolska, K. Suchorab, M. Frelek-Kozak, Ł. Kurpaska, J. Jagielski; Surface and in-depth structural changes in nuclear graphite irradiated with noble gases described with Raman imaging; Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms; Vol. 538 (2023) p. 103-109; DOI: 10.1016/j.nimb.2023.02.036

P. Kot, M. Wroński, A. Baczmański, A. Ludwik, S. Wroński, K. Wierzbanowski, Ch. Scheffzük, J. Pilch, G. Farkas, A novel method of experimental determination of grain stresses and critical resolved shear stresses for slip and twin systems in a magnesium alloy, Measurement, 2023, 113469, DOI: https://doi.org/10.1016/j.measurement.2023.113469

INFRASTRACTURE AT THE DISPOSAL OF THE GROUP

High-Resolution Field Emission Transmission Electron Microscope System JEOL JEM–F200

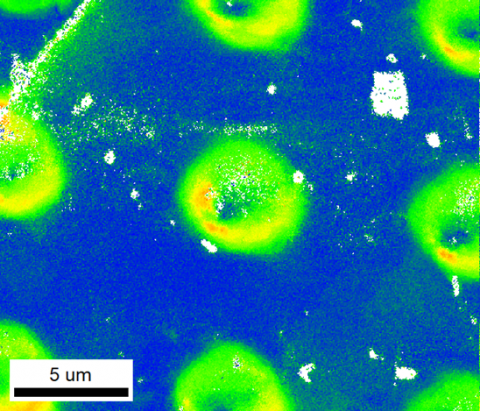

GND (Grain Necessary Dislocations) EBSD map (left/first)

and corresponding SEM image of Fe sample after spherical nanoindentation (right/second)

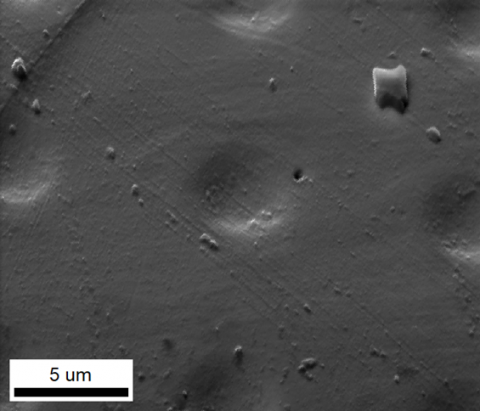

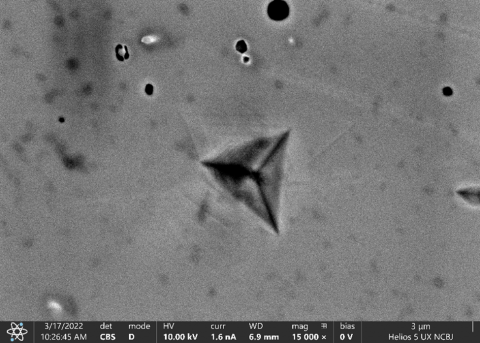

SEM BSE image in channelling contrast of 310 steel after nanoindentation showing the slip traces (left/first)

and Molecular Dynamic (MD) simulation image of the atomic displacement for the [110] orientation at the maximum indentation depth after

indentation; pile-ups formed and slip directions in agreement with SEM image (right/second)

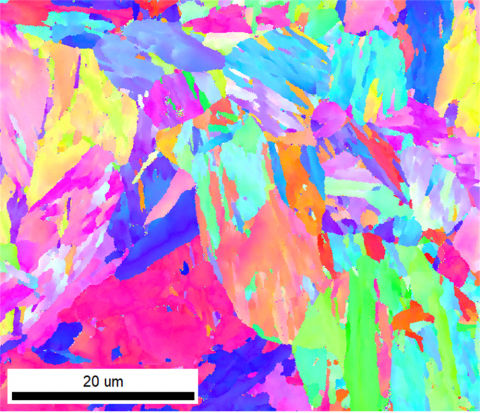

EBSD orientation image of Eurofer97 steel

SFT on {111} planes observed along [011] FCC zone axis in the area below

nanoindentation of HEA using high-resolution TEM (HRTEM) technique

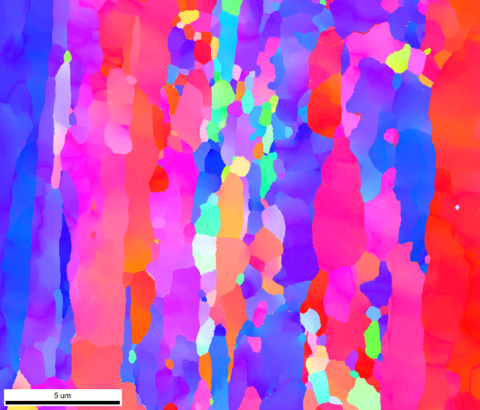

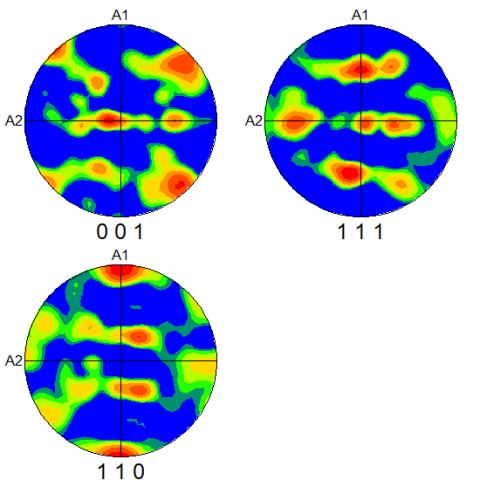

EBSD orientation image of HEA (left/first) and its texture representation in pole figures (right/second)

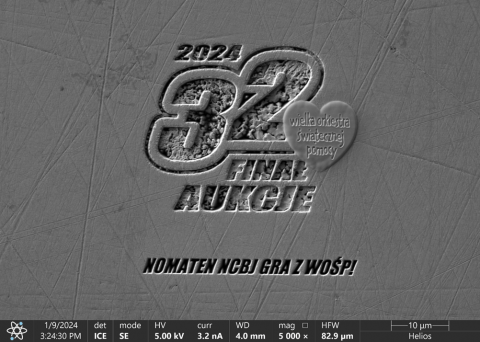

Logotype of the 32nd WOŚP Finale "sculpted with atoms"

using FIB technique in silver heart >> probably the tiniest heart in the World !!!

![Molecular Dynamic (MD) simulation image of the atomic displacement for the [110] orientation at the maximum indentation depth after indentation; pile-ups formed and slip directions in agreement with SEM image Molecular Dynamic (MD) simulation image of the atomic displacement for the [110] orientation at the maximum indentation depth after indentation; pile-ups formed and slip directions in agreement with SEM image](/sites/default/files/styles/large/public/field/image/7.png?itok=ycanAOkm)

![SFT on {111} planes observed along [011] FCC zone axis in the area below nanoindentation of HEA using high-resolution TEM (HRTEM) technique SFT on {111} planes observed along [011] FCC zone axis in the area below nanoindentation of HEA using high-resolution TEM (HRTEM) technique](/sites/default/files/styles/large/public/field/image/9.png?itok=PE719euk)

![Molecular Dynamic (MD) simulation image of the atomic displacement for the [110] orientation at the maximum indentation depth after indentation; pile-ups formed and slip directions in agreement with SEM image Molecular Dynamic (MD) simulation image of the atomic displacement for the [110] orientation at the maximum indentation depth after indentation; pile-ups formed and slip directions in agreement with SEM image](/sites/default/files/styles/thumbnail/public/field/image/7.png?itok=mCygRrnd)

![SFT on {111} planes observed along [011] FCC zone axis in the area below nanoindentation of HEA using high-resolution TEM (HRTEM) technique SFT on {111} planes observed along [011] FCC zone axis in the area below nanoindentation of HEA using high-resolution TEM (HRTEM) technique](/sites/default/files/styles/thumbnail/public/field/image/9.png?itok=XdW4lE9i)