Materials Design & Manufacturing

GROUP LEADER: Silvia Bonfanti, PhD

Dr. Silvia Bonfanti leads innovative research at the intersection of computational physics and materials engineering. Her background is in theoretical and computational physics, with a focus on molecular simulations and machine learning for predicting the behavior of complex materials. Her current work focuses on disordered materials, such as glasses and metallic glasses, high entropy alloys, and mechanical metamaterials. She addresses the core challenge of bridging simulation and experimental validation by integrating theoretical models, data driven methods, density functional theory and molecular dynamics. This is coupled with targeted experimental testing in coatings and 3D printing of metallic systems.

She is currently Assistant Professor at NOMATEN CoE at the National Centre for Nuclear Research (NCBJ) in Poland, and was appointed leader of the “Material Design & Manufacturing Group” in September 2025. Previously, she held research fellow appointments at Italy’s National Research Council (CNR – ICMATE of Milan) and at the University of Milan. She holds a cotutelle PhD from the University of Insubria of Como and the University of Montpellier (2016).

Dr. Bonfanti is Principal Investigator of two competitive Polish grants: SONATA BIS 13 (National Science Centre, Poland; ~€460,000) and FIRST TEAM FENG (Foundation for Polish Science; ~€950,000; co-financed by the European Union), both running through 2028. Since 2023 she is also serving as Working Group Leader (WP2) in COST Action DAEMON, coordinating European collaboration on machine learning for materials science.

Google Scholar: https://scholar.google.com/citations?user=l4v80ocAAAAJ&hl=en

ORCID: https://orcid.org/0000-0002-0323-8714

STRUCTURE OF THE GROUP

- Silvia Bonfanti (Research Group Leader)

- Anshul Parmar (Postdoctoral Researcher, Senior)

- Dmytro Khomenko (Postdoctoral Researcher, Senior)

- Amin Esfandiarpour (Postdoctoral Researcher, Senior)

- Filip Kaśkosz (Postdoctoral Researcher, Junior)

- Antoni Wadowski (PhD Student)

- Alex Peichen Wang (PhD Student)

DESCRIPTION OF THE SCIENTIFIC ACTIVITIES

The Material Design & Manufacturing Group advances materials design by integrating density functional theory (DFT), large-scale molecular dynamics, and data-driven models like machine learning and machine learning interatomic potentials (MLIPs) with targeted experimental validation at NOMATEN. Our focus is on disordered and multicomponent alloys, where local structural heterogeneity dictates macroscopic properties. We aim to translate atomic-scale insights into practical, engineerable outcomes via iterative "simulate → design → prototype → test" workflows.

Key research areas include:

- Developing and validating novel machine learning interatomic potentials for disordered materials.

- Mapping the composition-structure-property relationships in high entropy metallic glasses and high-entropy alloys.

- Designing mechanical metamaterials with predictive pipelines for performance and failure.

- Investigating novel high-entropy alloys compositions for nuclear applications.

We prioritize reproducible datasets, uncertainty quantification in models, and rigorous benchmarking against ab initio calculations and experiments, including coatings and 3D printing of metallic systems.

RESEARCH HIGHLIGHTS – Some recent works

Machine Learning Potentials for Metallic Glasses

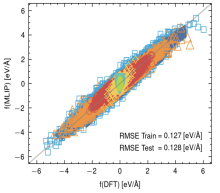

The development of interatomic potentials is key to guiding modeling at larger scales and informing experiments. In recent years, machine learning interatomic potentials (MLIPs) have been employed with great success. Typically, one trains the ML architecture on a large dataset of density functional theory (DFT) calculations for the target system. However, for disordered systems such as metallic glasses, the challenge lies in identifying "representative" disordered structures that accurately capture experimental features. The rugged and complex energy landscape of glasses makes this task particularly difficult.

We addressed this scientific question in our paper by using a surrogate Lennard-Jones (LJ) model parameterized with DFT for a real system (CuZrAl metallic glass). Through swap Monte Carlo (MC) and molecular dynamics (MD), we access glassy states down to deeply supercooled regimes. By taking DFT snapshots without performing expensive relaxations, we efficiently train the MLIP. This method is computationally efficient and produces models that describe experimental results well—often better than existing semi-empirical potentials for metallic systems, such as the Embedded Atom Method (EAM). The DFT dataset is available on the NOMAD platform: https://nomad-lab.eu/prod/v1/gui/dataset/id/uziqhPzPQUuyvqD5QSHJUQ

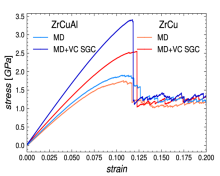

Mechanical Response of Simulated Metallic Glasses

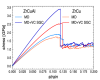

Building on model metallic glasses, we explore realistic metallic glass systems (binary ZrCu and ternary ZrCuAl) and study their properties. We introduce a hybrid method (Variance-Constrained Semi-Grand Canonical Monte Carlo coupled with molecular dynamics (MD) and realistic Embedded Atom Method (EAM) potentials for metallic glasses) to access deeper states in the energy landscape. This allows us to compute the relaxation dynamics of the system and observe a speedup of about 8 orders of magnitude in the binary case and 10 in the ternary, bridging the gap between computational timescales and experimental realities. This differs from polydisperse systems, as it involves real systems where particle radii are dictated by nature rather than artificially altered. The plot represents the mechanical properties of the sheared system: when well-relaxed using the hybrid method, the stress-strain curve exhibits a sharp drop, corresponding to realistic fracture behavior in glasses (e.g., brittle failure with defined shear bands). Conventional MD simulations have so far only shown an overshoot with more gradual, diffuse plasticity. The procedure is generic and can be applied to other metallic glass compositions, opening doors for advanced materials design in nuclear and engineering applications.

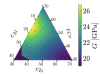

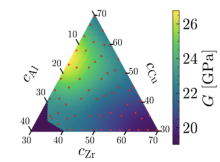

Mechanical composition landscape exploration for a ternary metallic glass with Bayesian Optimization

In this work, we explore the mechanical properties of metallic glasses across the compositional space of the CuZrAl system. We employ a Bayesian optimization method to efficiently map the landscape and identify optimal compositions for enhanced mechanical performance, such as shear modulus (G) and yield stress (τ_y). The red points in the plot indicate the compositions explored by the algorithm, which rapidly converges on regions of high property values through uncertainty-guided sampling. This approach requires only a few dozen iterations to reveal the maximum, demonstrating significant speedup over exhaustive searches.

From High Entropy alloys to High Entropy Metallic Glasses

In this work, we investigate how varying the degree of disorder (amorphization parameter α) affects the vibrational properties of high-entropy alloys (HEAs), from fully crystalline to partially crystalline and amorphous (glassy) states. Using molecular dynamics simulations, we analyze the Cantor HEA (CrMnFeCoNi), one of the most studied equiatomic compositions. To assess chemical ordering in crystalline HEAs, we perform a hybrid swap Monte Carlo + MD procedure, starting from random configurations and iteratively swapping atom pairs to find more stable chemical arrangements. This reveals quasilocalized vibrational modes that persist across different levels of disorder, with the density of states following a ω⁴ dependence typical of glasses, but with a larger prefactor in chemically ordered crystals compared to random ones. The plot shows short-range order parameters (Warren-Cowley) for atomic pairs, indicating preferred clustering (peaks) compared to fully random configurations (circular baseline), highlighting the impact of compositional disorder in HEA.

Mechanical Metamaterials – Simulations to Design and failure prediction

Mechanical metamaterials are engineered materials whose properties arise from their carefully designed microstructure rather than the base material composition. These artificial structures can exhibit extraordinary behaviors not found in natural materials, such as auxeticity (expanding laterally when stretched, i.e., negative Poisson's ratio), enhanced stiffness-to-weight ratios, or tunable energy absorption. They are often created from lattice or beam networks and have applications in aerospace, biomedicine, and protective gear, where optimizing for multiple conflicting properties like fracture resistance and deformation response is key.

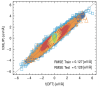

In this work, we develop simulation-to-design pipelines using Monte Carlo optimization to balance auxeticity and fracture toughness in disordered beam metamaterials derived from random particle packings. By varying optimization weights, we identify a Pareto front revealing a trade-off: high auxeticity leads to bending-dominated deformation and lower energy absorption, while prioritizing toughness results in stretch-dominated failure with diffuse damage patterns. Simulations under tension predict failure modes, validated against experiments on 3D-printed samples, showing good agreement in elastic regimes. This approach enables robust design under load, generalizable for multi-objective metamaterial engineering.