Multiscale Hybrid Modeling of Materials

GROUP LEADER: Javier Dominguez, Ph.D., DSc

Dr. Javier Dominguez received his Ph.D. in Computational and Applied Physics with Summa Cum Laude honors from the National University of Mexico. He continued his academic training at Stony Brook University, where he worked on plasma–material interaction modeling in collaboration with the Princeton Plasma Physics Laboratory. He later joined the Max Planck Institute for Plasma Physics in Germany as an Alexander von Humboldt Research Fellow, also supported by a Siemens Foundation scholarship. In recognition of his innovative contributions to nuclear materials research, he received the IAEA International Challenge Prize for developing a machine learning tool dedicated to the analysis of radiation-induced defects. In 2023, he obtained his habilitation in Physics and was appointed Institute Professor at NCBJ.

At NOMATEN CoE, Dr. Dominguez leads a research group dedicated to developing multiscale numerical models to understand the response of advanced materials, including high-entropy alloys, under extreme environments such as high temperature and irradiation. His team collaborates with CEA (France) and other major European institutions, integrating modeling and experiments to support the design of materials for fusion, fission, and industrial applications. He has published over 60 peer-reviewed journal articles, is actively engaged in European scientific networks, and contributes to the international community through editorial, reviewer, and leadership roles.

STRUCTURE OF THE GROUP:

Javier Dominguez (Research Group Leader)

Karol Frydrych (Postdoctoral Researcher)

Amil Aligayev (Postdoctoral Researcher)

Mark Fedorov (Postdoctoral Researcher)

Tymofii Khvan (Postdoctoral Researcher)

Bakhtiyar Mammadli (Research Assistant)

Amirhossein Naghdi Dorabati (Research Assistant)

Michal Pecelerowicz (Data Management)

DESCRIPTION OF THE SCIENTIFIC ACTIVITIES

The group’s scientific activities are dedicated to advancing multiscale modelling and artificial intelligence for predicting the mechanical, electronical, optical, and functional properties of structural and nuclear materials under extreme environments. Research spans atomistic to continuum scales, providing a mechanistic understanding of deformation, irradiation damage, and failure, and integrates machine learning and explainable AI to develop predictive surrogate models that link simulations with experimental data. These approaches identify the key parameters controlling strength, ductility, and radiation tolerance, while also offering uncertainty quantification to accelerate materials qualification for nuclear energy systems.

In addition to nuclear structural applications, multiscale modelling frameworks are extended to electrochemical catalysis, hydrogen storage, and water splitting. Here, ab initio and quantum chemical software is utilized to modelling and AI tools are used to unravel reaction mechanisms, optimize catalytic interfaces, and design materials with improved efficiency and stability for sustainable energy conversion and storage.

By combining physics-based modelling with data-driven methods, the group delivers predictive and interpretable insights that support both materials roadmap and the broader development of advanced energy technologies.

The core research pillars of our group encompass the following key areas:

Multiscale Modelling of Nuclear Materials – linking atomistic, mesoscopic, and continuum scales to understand irradiation damage, deformation mechanisms, and mechanical property evolution in steels, Ni-based alloys, high-entropy alloys, and tungsten-based systems.

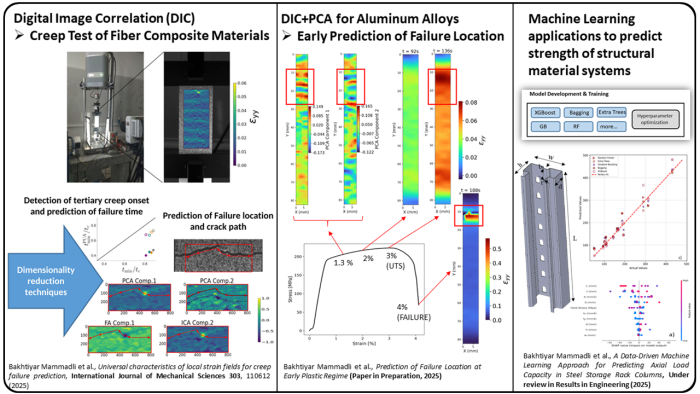

Artificial Intelligence and Explainable Machine Learning – developing predictive and interpretable models that connect experimental datasets with simulations, enabling accelerated qualification of structural materials and protective coatings for fusion and fission applications.

Protective Coatings and Functional Ceramics – modelling and AI-driven design of amorphous and doped alumina coatings for Eurofer97, addressing corrosion resistance, tritium permeation, and high-temperature stability in breeder blanket environments.

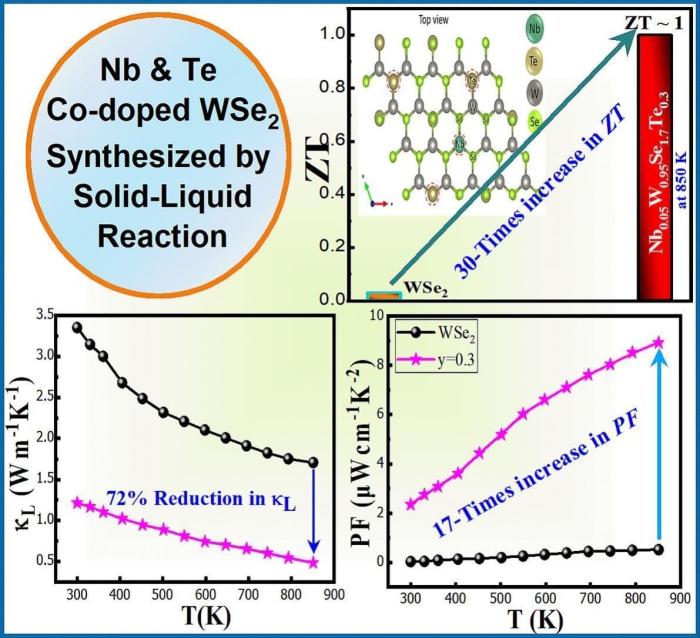

Energy Conversion and Storage Materials – applying multiscale modelling and AI to electrochemical catalysis, hydrogen storage, and water splitting, with the aim of optimizing catalytic interfaces and designing efficient, durable materials for sustainable energy technologies.

Publications:

Frydrych, K., 2025. Some notes about simulating nanoindentation with imperfect Berkovich tip. Modelling and Simulation in Materials Science and Engineering, 33(4), p.045016. https://iopscience.iop.org/article/10.1088/1361-651X/add950/meta

Bakhtiyar Mammadli, K. Frydrych et al., Universal characteristics of local strain fields for creep failure prediction, International Journal of Mechanical Sciences 303, 110612 (2025),, https://doi.org/10.1016/j.ijmecsci.2025.110612 .

Mazhar Hussain Danish, Amil Aligayev, Zahir Muhammad, Tao Chen, Adil Mansoor, Zia Ur Rahman, F.J. Dominguez-Gutierrez et al. Synergistic modulation of band structure and phonon transport for higher thermoelectric performance of WSe2. Chemical Engineering Journal 518, 164510 (2025). https://doi.org/10.1016/j.cej.2025.164510

Tymofii Khvan, Ludovic Noels, Dmitry Terentyev, Enrico Corniani, Peter Hähner, Chih-Cheng Chang. Development of a semi-empirical approach correlating ion- and neutron-induced hardening in Eurofer97 using nanoindentation and crystal plasticity finite element method. Journal of Materials Research and Technology 38, 5780 (2025).

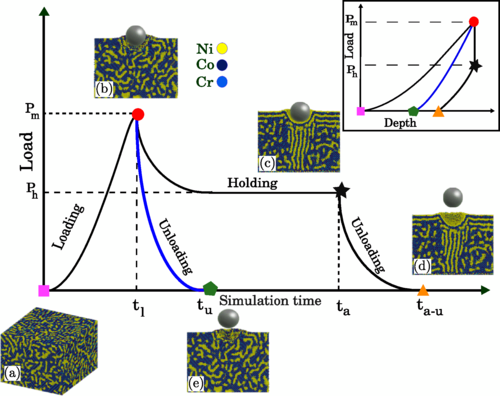

A. Naghdi, F.J. Domínguez-Gutiérrez, W. Y. Huo, K. Karimi et al. Dynamic Nanoindentation and Short-Range Order in Equiatomic NiCoCr Medium-Entropy Alloy Lead to Novel Density Wave Ordering. Phys. Rev. Lett. 132, 116101 (2024).

E. Wyszkowska, C. Mieszczyński, A. Aligayev, A. Azarov, W. Chromiński, D. Kalita, A. Kosińska, F. J. Dominguez-Gutierrez, L. Kurpaska, I Jóźwik, J. Jagielski. Nanoscale Defect Formation in fcc Ni and Low-Fe Content NixFe1-x Single Crystals Induced by Self-Ion Irradiation. Nanoscale 17, 15841, (2025). https://doi.org/10.1039/D5NR00117J

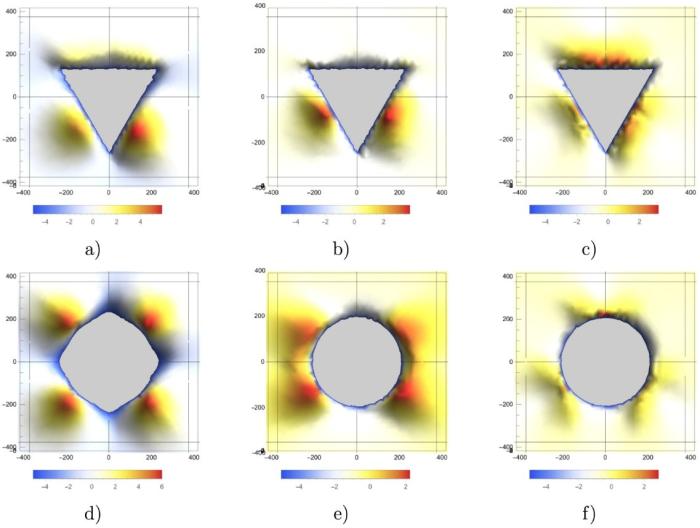

The influence of crystallographic orientation on surface topography for Berkovich indentation and crystal orientation: (a) 100, (b) 110 and (c) 111. For comparison, the results of spherical indentation for the same orientation are provided in (d)–(f) (d) 100, (e) 110 and (f) 111. To better visualize the surface patterns, the part of the surface inside the indent is hidden.