NOMATEN HYBRID-SEMINAR April 1: Investigation of High Stress Dynamics in Materials Engineering Using the Shimadzu HITS-X machine, HPV-X2 High Speed Camera and Digital Image Correlation Software

In-person: NOMATEN seminar room (102)

NOMATEN HYBRID-SEMINAR

online: https://meet.goto.com/NCBJmeetings/nomaten-seminar

In-person: NOMATEN seminar room (102)

Tuesday, April 1 st, 2025 1 PM (CET)

Investigation of High Stress Dynamics in Materials Engineering Using the Shimadzu HITS-X machine, HPV-X2 High Speed Camera and Digital Image Correlation Software

Jan Podgórski

Shim-Pol Company

Abstract:

The use of composite materials is constantly evolving, requiring further development and optimization of the mechanical properties of these materials. A number of strategies have been used in the past, choosing different types of fibers, resins and innovative geometric orientations for these fiber-reinforced plastics. Today's discussion will focus on polymer resins and their behavior during dynamic deformation. It is known that the mechanical properties of polymeric materials show a dependence on the strain rate. To properly observe the fracture behavior and stress characteristics, state-of-the-art technologies have been used. Shimadzu's HPV-X2 ultra high-speed video camera (10 million frames/second) combined with Shimadzu's HITS-T10 testing machine (with dynamic tensile speeds of up to 20 meters/second) and DIC software have been used to visualize stress concentrations, crack propagation and stress gradients after crack initiation. These advanced tools enable researchers and materials engineers to optimize polymer materials used in composites to improve their performance under demanding conditions.

Fig. 1: Shimadzu HPV-X2 ultra high-speed camera

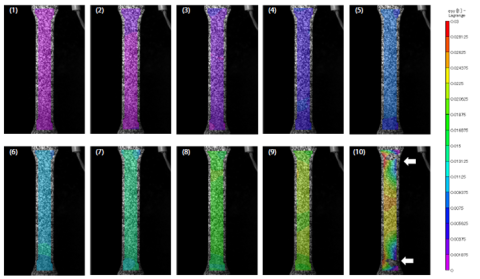

Fig. 2. Results of DIC analysis of test sample (dog bone), stress distribution

in the longitudinal direction

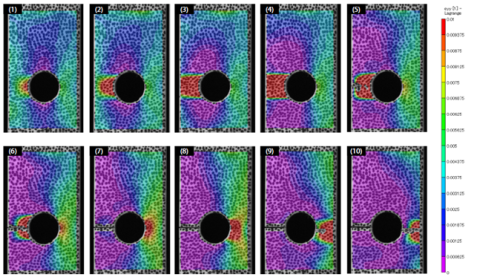

Fig. 3. DIC analysis results of the test sample (with hole), stress distribution

in the longitudinal direction

Keywords: composites, high dynamic stress, ultrafast cameras, materials engineering, digital image correlation (DIC)

Bio:

Jan Podgórski - Scientific Representative at Shim-Pol Company for Material Testing Machines and Materials Engineering.

At the start of my career, my emphasis was in environmental chemistry, specifically analytical techniques which included gas and liquid chromatography along with a wide range of detection techniques including MS.

With vast knowledge of chromatography, my interests then migrated to pharmaceuticals and drug delivery systems such as inhalation, transdermal and micro-needle delivery. Here I expanded my analytical knowledge with spectroscopic techniques such as FTIR and UV.

My knowledge and experience in analytical chemistry techniques has benefitted me greatly in my current interest in materials engineering, with an emphasis on micro and nano-structures of materials. Static, dynamic and hardness testing of materials coupled with imaging techniques is my current focus since 2014. With the use of high speed cameras as well as non-destructive (NDI) techniques such as industrial computer tomography and ultrasonic shearography, I try to provide my customers with the best options for further research in their specific applications.