NOMATEN SEMINAR on March 1 2020: Ductile amorphous oxide coatings and their key enabling role for next generation nuclear technologies

NOMATEN SEMINAR

Tuesday, MARCH 1st 2022 13:00 (1.00PM CET)

http://www.gotomeet.me/NCBJmeetings/nomaten-seminar

Ductile amorphous oxide coatings and their key enabling role for next generation nuclear technologies: heavy liquid metal cooled fast reactors and fusion

Fabio di Fonzo PhD, Italian Institute of Technology - Center for Nano Science and Technology - Genova, Italy

Abstract:

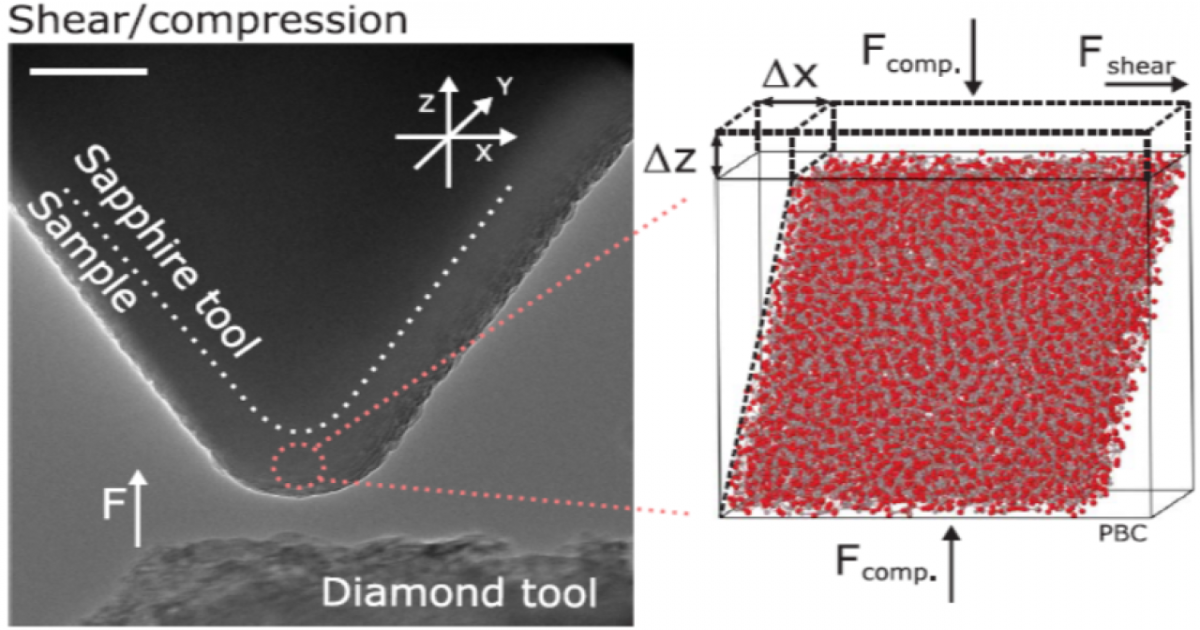

In this seminar I will present our recent results on ductile amorphous oxide coatings and their key enabling role for next generation nuclear technologies: heavy liquid metal cooled fast reactors and thermonuclear fusion. These unique class of amorphous ceramics exhibits an elastoplastic response under both tensile and compressive tests at room temperature (E. Frankberg et al. Science, 2019). A yield stress as high as 4 GPa (tensile and compressive) has been measured, with a plastic deformation as high as 7% in tension and 100% in compression.

Whilst we are still investigating the exact microscopic mechanism is still unknown, we observed that the plastic deformation of the material resembles viscous flow, in which no observable necking occurs and the stress is proportional to strain rate with no other strengthening mechanisms observed. This initial finding suggests that viscous creep of amorphous materials can be activated even at room temperature if sufficiently high stress levels can be reached, hence inducing yielding instead of brittle fracture. The experimental and theoretical work performed so far portrait a scenario in which three conditions seem to be necessary: structural homogeneity; high mass/atomic density; absence of defects down to the nm range; bonds flexible enough to undergo changes in coordination number as well as of neighbour. SEM in situ micromechanical tests suggest that this elastoplastic behaviour is maintained even for volumes of several microns cube. We studied how this amorphous oxides behaves under heavy ion irradiation finding a peculiar crystallization behaviour with dose, with detectable damages only above 150 dpa (F. G. Ferré et al. Scientific Reports 2016).

Besides these unique mechanical properties, the amorphous oxide coatings exhibit extreme stability under thermal stresses, near zero permeability to gases and inertness with respect to heavy liquid metal (Pb, PbBi, LiPb) corrosion. Indeed, we will show how these materials, by in the form of coatings on structural steels, are key for next generation fast nuclear reactors and magnetically confined nuclear fusion, enabling the design of innovative and economically attractive power plants.

Acta Materialia 61 (7), 2662-2670, 2013

Corrosion Science 77, 375-378, 2013

Scientific Reports 6, 33478, 2016

Corrosion Science 124, 80-92, 2017

Acta Materialia 143, 156-165, 2018

Journal of Nuclear Materials 512, 118-125, 2018

Nuclear Fusion 58 (12), 126007, 2018

Journal of Nuclear Materials 516, 160-168, 2019

Fusion Engineering and Design, 2019

Science 366 (6467), 864-869, 2019

Fusion Eng. and Design 158, 111759 3, 2020

Surf. and Coat. Tech. 386, 125491 1, 2020

IAEA TECDOC SERIES, 195, 2020

Fusion Engineering and Design 170, 112521, 2021

NUCLEAR FUSION 61 (1), 2021

Bio:

Dr. Fabio Di Fonzo is team leader and technologist at the Center for Nano Science and Technology@PoliMi of the Italian Institute of Technology and leads the “Nanomaterials and Nanomanufacturing for Energy and Environment” Group. He got his Ph.D. in Radiation Science and Technology from the Nuclear Engineering Department of the Politecnico di Milano University, Italy, and two MS in Mechanical Engineering from the University of Minnesota, US, and from the Politecnico di Milano University, Italy, (Energy Major). In 2012 he got the position of Team Leader at CNST and since then he has his own independent research group, currently comprising an average of 12 members (postdocss, PhDs, MS students).

Capitalizing on his previous experiences, he established a multi-disciplinary research team, made of physicists, chemists, material scientists and engineers, supporting a synergistic and stimulating interaction in order to design and deliver innovative materials and manufacturing technologies with the goal to enable a CO2-free energy generation and storage society. His research focus is in gas phase self-assembly of functional nanostructured materials for energy conversion and storage. Main fields of application of the developed materials are: photovoltaics, solar fuels, fuel cells, batteries, safe and sustainable nuclear energy (fission and fusion). Basic understanding of the properties of functional nanomaterials is a focus of the research as well as upscaling of nano-manufacturing methods. Fabio Di Fonzo has so far authored 1 book chapter, 102 international peerreviewed journal articles (h-index=30 Scopus), several white papers and reports in the framework of the Italian Electrical System Research Funding and co-inventor of 6 patents. In 2020 he was awarded the SOFT Innovation prize for substantial contribution in the development of fusion energy technology.